Industrial sieves — also known as industrial screening machines or particle size separation equipment — are mechanical systems designed to separate, classify, or filter solid materials based on particle size. They are essential in industries such as food processing, pharmaceuticals, chemicals, and advanced manufacturing, where product consistency, contamination control, and regulatory compliance are critical.

Industrial sieving equipment is engineered for high-capacity performance, hygiene, and durability. These large volume systems handle bulk powders, granules, and even slurries, using technologies such as vibratory screening, centrifugal sifting, or ultrasonic sieving to move material across mesh screens. This process ensures fast, accurate, and repeatable separation of particles.

Why industrial sieves matter in manufacturing

Industrial sieves play a vital role in maintaining product quality, process efficiency, and regulatory compliance across a wide range of industries. By removing oversized particles, foreign bodies or product inconsistencies, they help ensure the uniformity and integrity of the final product.

In sectors like food processing and pharmaceutical manufacturing, industrial sieving also acts as a critical control point — reducing the risk of contamination and ensuring compliance with hygiene and safety standards. For manufacturers handling fine powders or sensitive bulk materials, the right sieving solution can dramatically reduce downtime, minimise waste, and improve yield.

Whether you’re producing flour, metal powder, excipients or chemical additives, integrating the correctly specified screening solution into your process line can improve product quality, protect equipment, optimise product yield and minimised the cost of product recall.

Types of industrial sieves: a comparison guide

Industrial sieves come in several designs, each suited to specific materials, throughput volumes, hygiene needs and environmental conditions. Here’s a breakdown of the most common types used in modern material handling:

Vibratory sieves

Use vibratory motors to promote product movement across mesh screens. Suitable for a wide range of dry powders and granules. Ideal for general-purpose particle sieving and high-throughput production lines.

Check sieving – also known as police sieving – is the most common type of industrial sieving. These sieves ensure product quality by:

- Removing foreign bodies: Ensuring no unexpected material has entered the product during processing.

- Breaking up lumps: Preventing agglomerates from passing through to the final product.

- Performing quality checks: Supporting product consistency and compliance with hygiene and safety standards.

A good example of check sieves would be the Farleygreene Slimline range.

Grading is a more precise operation than check sieving. It involves separating material into defined particle size ranges – or ‘cuts’ – to ensure that the particles in each cut are between a certain size. This is typically achieved by passing the product through up to four meshes with decreasing aperture sizes. A second sieve can be added downstream to create additional cuts if required or alternatively multiple single-deck sieves can be installed in a cascade.

A good example of grading sieves would be the Farleygreene Multiscreen range.

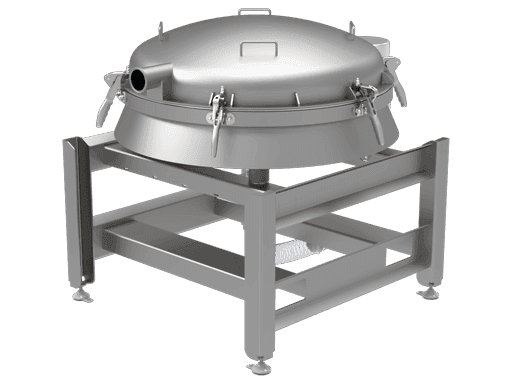

Centrifugal sieves use a high-speed rotating paddle system to propel product against the inner surface of a cylindrical mesh screen. The centrifugal force pushes material through the mesh while simultaneously helping to break down clumps.

These sieves are:

- High throughput systems: They offer significantly greater capacity than vibratory sieves for the same mesh area, making them ideal for bulk processing.

- Effective on sticky or compressed product: The internal paddles help disaggregate lumpy, greasy, or compacted materials.

- Less suitable for delicate applications: The force applied may damage or break down genuine oversize particles – such as grain husks or plastic packaging – potentially allowing unwanted material to pass through.

Centrifugal sifters are commonly used in food, chemical, and starch-based applications where throughput and flowability are key priorities.

A good example of centrifugal or rotary sieves would be the Farleygreene Rotary range.

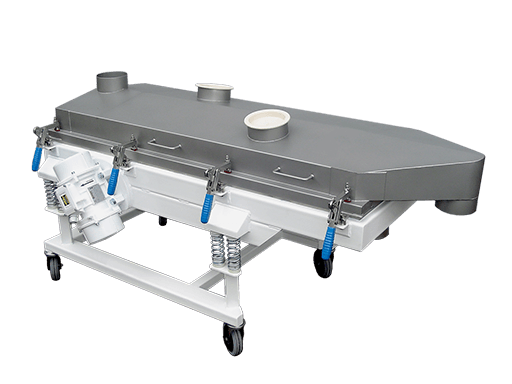

Linear sieving moves product in a straight line across a rectangular mesh screen. This linear motion gives particles more time to pass through the mesh, improving separation efficiency – especially for materials with a high percentage of oversize. It can be used with both grading and check sieving applications.

Because of their directional movement, linear sieves can sometimes replace part of a conveyor system, transporting product while simultaneously sieving. They can even be installed on a slight incline to lift product to the next stage in the process.

Linear sieving is especially useful for:

- Delicate or friable products: The gentle linear motion helps protect fragile materials from damage.

- Products with high oversize content: The extended length allows finer particles to fall through without being blocked by larger material.

- De-dusting or de-watering: Ideal for removing fine particles like flour or crumbs from finished products such as biscuits.

- Aligning capsules or tablets: In pharmaceutical and nutraceutical applications, linear sieves fitted with rows of parallel bars (instead of mesh) can efficiently align high-aspect-ratio products while still controlling size and flow.

A good example of centrifugal or rotary sieves would be the Farleygreene Segregator range.

Key applications of industrial sieves by industry

Industrial sieves are used across virtually every processing sector — but requirements vary significantly depending on the material, hygiene regulations, and operating environment. Here’s how sieving supports key industries:

Food industry

Used to sieve flour, sugar, spices, starches and flavourings. Farleygreene’s hygienically designed sieving systems help ensure product consistency, prevent contamination, and support compliance with food safety regulations such as CE, UKCA, FDA and EC 1935/2004. Check sieves are commonly used as a critical control point in food production lines.

Pharmaceuticals

Sieving plays a vital role in removing foreign bodies, separating particle sizes, and maintaining GMP compliance. Farleygreene supplies pharmaceutical-grade sieves for handling APIs, excipients, and coated ingredients — where hygienic design, traceability and ease of cleaning are essential.

Chemicals

Industrial sieving is used for screening pigments, polymers, resins and fine chemical powders. Centrifugal sifters are often preferred for sticky, greasy or hazardous materials due to their enclosed design, while ultrasonic systems support fine powder classification without mesh blinding.

Additive manufacturing

In powder-based manufacturing, particularly metal additive manufacturing, sieving ensures ultra-fine particle control, dust containment, and recyclability of high-value powders. Ultrasonic sieving systems help maintain powder integrity during reuse cycles, supporting both quality and cost-efficiency.

Other processing industries

From paints and coatings to plastics and recycling, sieves help separate useful product from waste, improve flow characteristics, and reduce processing faults.

How to choose the right industrial sieve for your process

Selecting the right industrial sieve depends on a detailed understanding of your product characteristics, throughput requirements, environmental constraints, and regulatory needs. Here are the key factors to consider:

- Material properties: Is the product free-flowing, sticky, abrasive, heat-sensitive or electrostatic? These characteristics influence whether a vibratory, check, linear, grading, centrifugal, or ultrasonic sieving system is best suited.

- Desired particle size: What size cut or separation range are you targeting? The mesh aperture, number of decks, and sieve type determine separation accuracy and final product consistency.

- Wet or dry process: Will the material be screened as a dry powder or as part of a slurry or suspension? Equipment selection must match the moisture content and flow behaviour of the material.

- Throughput volume: Is your production continuous or batch-based? Higher-volume lines may benefit from multi-deck systems or automated sieving solutions to maintain throughput without bottlenecks.

- Hygiene requirements: For sectors like food and pharmaceuticals, look for CIP-compatible and hygienically designed machines that meet EC 1935/2004, FDA or GMP standards.

- Space and integration: Is the unit being added to an existing line or installed as part of a new system? Consider access, footprint, and whether the sieve needs to connect with sack tip stations, conveyors, or other bulk handling equipment.

An in-house product trial can be invaluable in confirming performance before purchase. Farleygreene’s testing facility is available to help customers validate sieve selection using real product samples.

Important industrial sieve features to evaluate before buying

When comparing industrial sieving equipment, it’s important to assess performance, hygiene, safety and maintenance features. Consider the following:

- Screen changeover: How easily can the mesh be accessed and replaced? Fast-change or tool-free systems help minimise downtime during cleaning or product changeover.

- Dust containment: Does the system effectively capture and contain fine particles? Dust-tight design and sealed connections protect operators, prevent cross-contamination, and help meet environmental and health regulations.

- Noise levels: Is the equipment suitable for continuous operation in a production environment? Low-noise motors and vibration isolation features can reduce fatigue and help meet workplace noise standards.

- Automation options: Can the sieve be integrated with PLCs or SCADA systems? Automated monitoring of throughput and vibration supports Industry 4.0 and predictive maintenance strategies.

- Build quality: Are product contact parts made from 304 or 316L stainless steel, with smooth welds and polished surfaces? High-grade materials support hygienic design and compliance with EC 1935/2004 or FDA regulations.

- Footprint and mobility: Does the sieve fit your available space, and can it be repositioned easily? Compact or mobile configurations are useful for facilities with limited layout flexibility or frequent cleaning cycles.

Choosing a supplier that can tailor equipment to your specific process — rather than offering a one-size-fits-all system — will ensure better performance, faster ROI, and long-term reliability.

Common mistakes to avoid when choosing industrial sieves

Avoiding these common pitfalls will help ensure you get the best value and long-term performance from your industrial sieving solution:

- Underestimating throughput needs: Choosing an undersized sieve can create production bottlenecks and reduce overall efficiency. Always consider future capacity and potential product changes when specifying equipment.

- Choosing the wrong mesh size: An incorrect mesh aperture can lead to excessive product losses, inconsistent separation, or contamination risk. Accurate particle size distribution data is essential for correct specification.

- Ignoring cleanability: Equipment that’s difficult to access or sanitise increases downtime and can compromise hygiene compliance, especially in food or pharmaceutical environments.

- Overlooking regulatory needs: Failing to meet certifications such as ATEX can result in delayed installations, increased costs, or audit failures. Always confirm requirements during the procurement stage.

- Failing to futureproof the equipment: Lack of scalability or modular design can restrict your ability to adapt to new product lines, tighter regulations, or growth. Choose systems that allow for flexibility and upgradeability.

Regulatory compliance and industry standards for industrial sieves

In regulated industries, industrial sieving equipment must meet strict compliance standards — not just in performance, but also in construction, materials and traceability documentation. Below are the key certifications and frameworks to consider:

- CE and UKCA marking: Demonstrates compliance with UK and EU machinery safety directives, including essential health and safety requirements for industrial equipment.

- FDA and EC 1935/2004: Confirms that all materials in contact with food are safe, inert and suitable for hygienic processing under both US and EU legislation.

- ATEX compliance: Required for processing environments with combustible dusts or flammable vapours. ATEX-certified sieves reduce the risk of ignition and protect personnel in explosive atmospheres.

- ISO 9001: Verifies that the manufacturer maintains a formal quality management system, with full process control and material traceability.

Farleygreene’s sieving systems are engineered to meet these international standards — offering peace of mind to buyers and engineers working in safety-critical or highly regulated sectors.

Customisation and integration options for industrial sieving solutions

Every process is different — and a standard off-the-shelf approach may not always meet your operational needs. Farleygreene specialises in custom-built industrial sieving systems that can be tailored to your process layout, material characteristics and compliance requirements. These systems are designed to integrate smoothly into existing lines or form part of a new bulk handling solution.

Key customisation and integration options include:

- Inlet and outlet configuration: Adjustments to suit upstream and downstream process equipment such as feed hoppers, conveyors, or discharge chutes. Oversize outlet configurations can be equipped with either DOSC (Disc Oversize Control) or BOSC (Balloon Oversize Control) systems, offering tailored flow control solutions for oversized material discharge.

- Mobile or static frames: Choose between wheeled units for flexible use or fixed frames for permanent installations — ideal for facilities with changing layouts or cleaning needs.

- Connection to process lines: Ensure a secure and hygienic material transfer using flanged, clamped or flexible connections that maintain dust-tight integrity.

- Surface finish and polish grade: Tailor internal finishes to hygiene requirements, from standard polish to mirror finish for high-care environments.

- Custom mesh sizes: Choose mesh apertures suited to your product’s particle size range, or specify wear-resistant screens for abrasive or high-throughput applications.

Farleygreene works closely with engineering and operations teams to deliver fully tailored sieving solutions that align with both performance and compliance goals.

Automation and digital integration of industrial sieves

As manufacturing evolves with digital transformation and Industry 4.0, the ability to integrate industrial sieving equipment with control systems and monitoring tools is becoming essential for process visibility, efficiency, and uptime.

Here are key automation and integration options used in modern sieving systems:

- PLC integration: Enables remote control and continuous monitoring of sieve performance via centralised control platforms. Helps reduce manual checks and supports automated process control.

- Sensor feedback: Sensors can detect product flow, vibration levels, or mesh tension — allowing for proactive adjustments and early detection of faults.

- Real-time alerts: Provides on-screen or automated notifications if vibration patterns change, throughput slows, or blockages occur — helping to prevent unplanned stoppages.

- Data logging: Records operational parameters such as run time, throughput, or error frequency. This supports traceability, quality assurance, and audit readiness in regulated environments.

These digital capabilities support improved productivity, reduce operator intervention, and give manufacturers greater control over product quality — especially in high-throughput production environments.

When to upgrade or replace your industrial sieve

Even the most reliable industrial sieving equipment has a finite lifespan. Recognising the signs that it’s time to replace or upgrade your system can help avoid costly failures, downtime or compliance issues.

Here’s when to consider an upgrade or replacement:

- Reduced throughput: A noticeable decline in processing speed may point to worn components, screen fatigue, or an undersized system no longer fit for increased production demands.

- Frequent mesh blockages: Persistent clogging — even after cleaning — may signal the need for ultrasonic mesh deblinding or a different sieve type better suited to your product.

- Long cleaning or changeover times: If hygiene or allergen controls are slowing operations, it could be time to switch to a more clean-in-place (CIP)-ready design or tool-free mesh access.

- Lack of integration or automation: Older sieves that can’t connect to digital control systems may limit productivity, traceability or remote monitoring.

- Rising maintenance costs: Frequent part replacement or unexpected downtime may suggest it’s more economical to invest in a new, high-efficiency screening system.

A sieving equipment audit from a specialist like Farleygreene can help assess your current setup and recommend the best upgrade path — whether through retrofitting, part replacement or full system renewal.

Why choose Farleygreene for industrial sieves

With nearly 50 years of experience and a reputation built on trust, precision, and long-term performance, Farleygreene is a leading UK manufacturer of industrial sieving and screening systems for demanding applications across food, pharmaceutical, chemical and general processing sectors.

Here’s what sets Farleygreene apart:

- Comprehensive product range: From check sieves and grading sieves to centrifugal sifters and ultrasonic screening systems — including small-batch and pilot-scale sieving units for R&D.

- Custom-built solutions: Equipment designed around your product characteristics, process layout, hygiene requirements, and regulatory standards — delivering tailored sieving solutions for every application.

- Certified UK manufacturing: 100% UK-designed and built, with full compliance to CE, UKCA, FDA, ATEX, EC 1935/2004, and ISO 9001.

- In-house product testing: A dedicated testing facility where you can trial your materials before purchase – helping ensure performance validation and specification confidence.

- Global distributor network: Localised sales and service support through a trusted international network — enabling fast response and consistent product availability.

- Dedicated after-sales service: Access to spare parts, technical support, and preventative servicing to maximise uptime and system reliability.

Explore Farleygreene’s full product range or get in touch with the team to find the right solution for your process.

Conclusion: selecting the right industrial sieving solution

Choosing the right industrial sieving solution is about more than throughput and mesh size. It’s about selecting a system that integrates seamlessly with your materials, process conditions, hygiene requirements and compliance responsibilities — while also supporting future growth, automation, and evolving standards.

Farleygreene brings together nearly five decades of engineering expertise, deep sector knowledge, and high quality UK manufacturing to support every stage of your sieving and screening equipment requirements — from product testing to after-sales service.

Ready to optimise your sieving process?

Contact Farleygreene to discuss your requirements, arrange a product trial, or speak to one of our experts.

…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………..

Glossary of industrial sieving terms

1. Check sieve: A safety sieve that removes contamination or oversized material before final processing or packaging.

2. Grading sieve: A multi-deck sieve that separates material into distinct particle size fractions.

3. Centrifugal sifter: A rotary sieve that uses paddles to push product through a cylindrical mesh screen — suitable for sticky or fatty materials.

4. Ultrasonic sieve: A vibratory sieve enhanced with high-frequency waves that prevent mesh blinding and improve performance with fine powders.

5. Linear sieve: A sieve using horizontal motion to move fragile or delicate products across a flat screen.

6. Vibratory sieve: A widely used type of sieve that moves product in circular or elliptical patterns across a mesh.

7. Mesh size: The number of openings per linear inch of mesh, determining what particle size is allowed to pass through.

8. Throughput: The quantity of material a sieve can process over a set period, typically measured in kg or tonnes per hour.

9. Contamination control: Measures taken to prevent foreign objects or oversized particles entering the final product.

10. Deblinding: The process of clearing blocked mesh apertures using methods like ultrasonics or mechanical agitation.

11. ATEX: A European directive for equipment used in potentially explosive atmospheres; critical for dust-prone processing areas.

12. EC 1935/2004: EU regulation ensuring all materials in contact with food are safe and traceable.

13. FDA compliance: Certification that equipment is suitable for food and pharmaceutical use under US regulations.

14. Noise attenuation: Design techniques that reduce machine noise during operation.

15. Support frame: The structural base that supports the sieve body and vibration mechanisms.

16. Batch processing: The handling of materials in defined, non-continuous quantities.

17. Inline integration: Installation of a sieve directly into the product flow line for continuous processing.

18. Hygienic design: Engineering principles that ensure equipment is easy to clean and free from contamination risks.

…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………..

FAQs about industrial sieves

1. What’s the difference between a vibratory sieve and a centrifugal sifter?

Vibratory sieves use vibration to move product over a mesh, while centrifugal sifters use paddles to push product through a cylindrical screen. The latter is better for sticky or fatty products.

2. Can I use the same sieve for multiple products?

Yes, provided it’s easy to clean and fitted with quick-change mesh systems. Many users keep spare mesh frames to switch between products with different size requirements.

3. What are grading sieves used for?

Grading sieves separate product into two or more particle size categories. They’re used when different size fractions need to be retained, reused, or discarded.

4. Are ultrasonic sieves worth the investment?

Yes — for fine, electrostatic or light powders that clog traditional meshes. Ultrasonics prevent blockages, improving efficiency and reducing downtime.

5. What’s the typical lifespan of a sieve mesh?

Mesh life varies by material and usage, but regular inspection and maintenance help extend its performance. Harsh products may require more frequent replacement. Having a spare mesh ring or basket ready can save costly downtime. Farleygreene’s After Sales Department can help you avoid this.

6. How do I know if a sieve is food-safe?

Look for CE, UKCA, FDA, and EC 1935/2004 certification. Also check for hygienic design features like polished welds and crevice-free construction.

7. Can industrial sieves handle wet materials?

Yes — certain sieves, particularly vibratory and linear models, can be configured to handle slurries, pastes, or moisture-rich materials.

8. Is ATEX certification really necessary?

In many industrial sieving applications ATEX compliance is critical due to the explosion risks posed by dust. Minimising the risk requires diligent equipment design and testing. For guidance on how ATEX regulations impact your specific process line, please consult a notified body.

9. How often should I clean my industrial sieve?

Cleaning frequency depends on product type and usage. For regulated sectors, cleaning may be required between every batch or shift.

10. Can I test my product before purchasing a sieve?

Yes — Farleygreene offers an in-house testing facility where you can trial equipment using your own product.