Farleygreene’s Sievmaster 500-S ensures the quality and consistency of quartz aggregate and inorganic pigments used in the manufacture of quartz surfaces.

Our customer specialises in the manufacture of natural quartz surfaces used both in domestic and business environments.

Natural quartz has a Mohs hardness of 7 out of 10 making it highly valued for its durability and resistance and is commonly used in the manufacture of high-end kitchen and bathroom quartz worktops. During the manufacture of quartz surfaces, different coloured quartz aggregate particles and pigments are combined and pressed into slabs, creating an array of various colours and patterns.

Our customer required a sieve to separate different sized quartz and pigment particles and achieve a throughput rate of 720 kilograms per hour to meet their manufacturing demands. It was vitally important that each particle sieved was the correct size to ensure the highest quality end-product and protect their reputation as a luxury brand. Particles that are too large or too small may be difficult to disperse evenly and would affect the final pattern and surface texture of the quartz slab. Sieving the particles would be an important step in the manufacturing process to help ensure that the final product meets the desired specifications.

To meet the customer’s requirement, Farleygreene’s Sievmaster 500-S proved the perfect solution. Known for its efficiency and reliability, the 500-S would ensure a consistent flow of sieved quartz aggregate and pigments, and the mobile design was easy to maneuver with one operator.

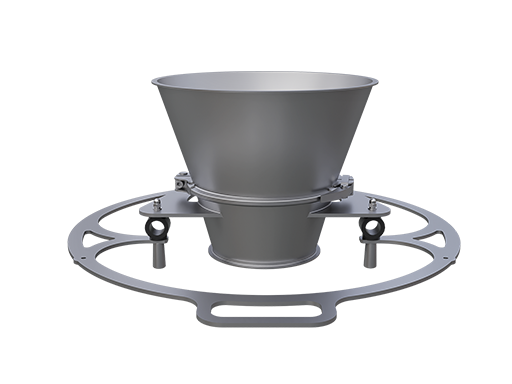

The flexibility and adaptability of the 500-S allowed for customisation to meet the specific requirements of the customer. The quartz would be gravity fed from a Metering Feeder directly into the sieve’s hopper and screened into the customer’s own collection container underneath. As per the customer’s request, Farleygreene adapted the standard 500-S frame by incorporating a bespoke square type support frame.

By providing a reliable, high-throughput sieving process, the Sievmaster 500-S enabled the customer to meet their manufacturing demands and maintain a steady production of quartz surfaces.

The customer was very satisfied with both the product and service provided by Farleygreene and later purchased four Sievmaster 200-S sieves to support their business growth. They provided the same level of accuracy and quality as the 500-S but were designed for smaller batch sizes. These additional sieves allowed for continuous operation without the need for switchover during product changes.

The collaboration between Farleygreene and the customer exemplified their commitment to delivering tailored solutions that align with the customer’s unique needs.

We have been supporting each of our customers through our global network of distributors since 1976, providing people with effective sieving and screening solutions. We help to either upgrade from your previous underperforming system, or with the implementation of a brand-new sieving process or installation within a new manufacturing line. We are committed to providing our customers with the most efficient, high-quality sieving machinery.

At Farleygreene, we ask ourselves 2 key questions when developing our products and services:

• How does this solution help our customers save time?

• How does this solution help our customers save money?

We are dedicated to working with our customers to develop cost and time-saving improvements without compromising quality.

Contact us today to find out how our sieving machines can support your production requirements.

Our customer required a sieve to separate different sized quartz and pigment particles and achieve a throughput rate of 720 kilograms per hour to meet their manufacturing demands. It was vitally important that each particle sieved was the correct size to ensure the highest quality end-product and protect their reputation as a luxury brand. Particles that are too large or too small may be difficult to disperse evenly and would affect the final pattern and surface texture of the quartz slab. Sieving the particles would be an important step in the manufacturing process to help ensure that the final product meets the desired specifications.

To meet the customer’s requirement, Farleygreene’s Sievmaster 500-S proved the perfect solution. Known for its efficiency and reliability, the 500-S would ensure a consistent flow of sieved quartz aggregate and pigments, and the mobile design was easy to maneuver with one operator.

The flexibility and adaptability of the 500-S allowed for customisation to meet the specific requirements of the customer. The quartz would be gravity fed from a Metering Feeder directly into the sieve’s hopper and screened into the customer’s own collection container underneath. As per the customer’s request, Farleygreene adapted the standard 500-S frame by incorporating a bespoke square type support frame.

By providing a reliable, high-throughput sieving process, the Sievmaster 500-S enabled the customer to meet their manufacturing demands and maintain a steady production of quartz surfaces.

The customer was very satisfied with both the product and service provided by Farleygreene and later purchased four Sievmaster 200-S sieves to support their business growth. They provided the same level of accuracy and quality as the 500-S but were designed for smaller batch sizes. These additional sieves allowed for continuous operation without the need for switchover during product changes.

The collaboration between Farleygreene and the customer exemplified their commitment to delivering tailored solutions that align with the customer’s unique needs.

We have been supporting each of our customers through our global network of distributors since 1976, providing people with effective sieving and screening solutions. We help to either upgrade from your previous underperforming system, or with the implementation of a brand-new sieving process or installation within a new manufacturing line. We are committed to providing our customers with the most efficient, high-quality sieving machinery.

At Farleygreene, we ask ourselves 2 key questions when developing our products and services:

• How does this solution help our customers save time?

• How does this solution help our customers save money?

We are dedicated to working with our customers to develop cost and time-saving improvements without compromising quality.

Contact us today to find out how our sieving machines can support your production requirements.

The Sievmaster 500-S is a vibratory sieve designed with a 500mm diameter stainless steel hopper built on a wheeled, mobile frame.

The Sievmaster 200-S is a small vibratory sieve designed with an open hopper. A circular frame supports the sieve and allows it to sit on top of a mixing bowl.

Make use of our demo fleet with two-weeks for free, or our in-house testing facility.