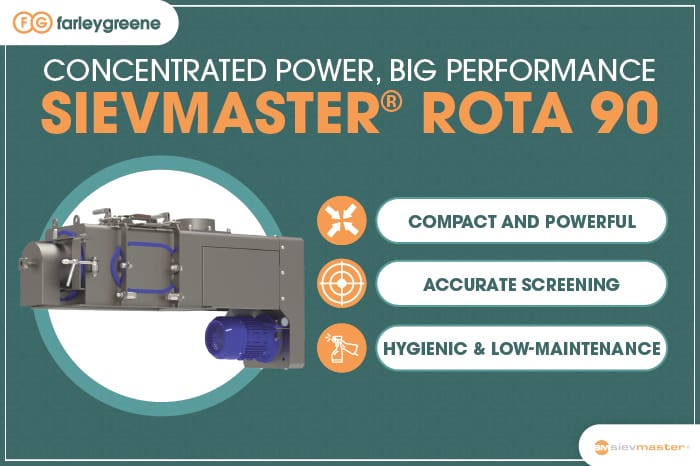

Small scale, high performance – the Sievmaster® Rota 90 is Farleygreene’s most compact centrifugal sifter, designed to provide high-quality, reliable sifting of fine powders and granules in production environments with limited space.

Notably, its enclosed design ensures dust-tight, hygienic operation, protecting product integrity while maintaining a clean work environment. It uses high-speed rotating paddles, which separates fine and coarse material with precision and breaks down compacted product in a single pass, delivering consistent, repeatable results every time.

Whether used as a standalone unit or integrated into existing production lines, the Rota 90 offers a versatile solution for manufacturers seeking compact, efficient, and easy-to-maintain sieving equipment.

Why Choose the Sievmaster® Rota 90?

Developed to meet the demands of industries where process hygiene, consistent product quality, and operational efficiency are critical, the Rota 90 combines thoughtful engineering with powerful performance in a small footprint.

- ✅ Compact & Efficient

Designed for confined production spaces and inline installations, the Rota 90 delivers high-volume bulk sieving for both wet and dry products without compromising throughput. Its compact footprint allows smaller-scale or secondary screening processes to run efficiently while keeping performance a priority, even in limited spaces. Despite its size, the Rota 90 achieves exceptional screening capacity, maintaining reliability and consistency in continuous operations.

- ✅Controlled Screening

At the heart of the Rota 90 is a high-speed paddle system that guides material evenly through the mesh, achieving accurate particle separation while simultaneously deagglomerating compacted material in a single pass. This controlled, non-vibratory action ensures consistent results for fine powders and granules, helping maintain product uniformity while reducing waste and protecting downstream equipment from oversized particles.

- ✅Hygienic & Easy to Maintain

The Rota 90’s fully enclosed, dust-tight design prevents product loss, contamination, and dust emissions, supporting a cleaner and safer production environment. Quick-release side door toggle clamps and tool-free access make internal inspection and cleaning fast and straightforward, while smooth, crevice-free surfaces and quick-change screens help maintain hygiene standards between product runs. Together, these features make maintenance both simple and safe, reducing downtime and ensuring compliance with strict industry regulations.

Discover the Rota Range: Hygienic, High-Performance Sieving for Any Process

The Rota 90 is part of Farleygreene’s wider Sievmaster® Rota Range, which includes models designed for varying capacities and process requirements. From small-scale food & drink setups to high-throughput chemical production systems, the Rota Range provides reliable, hygienic sieving solutions built to perform.

👉 Learn more about the full range: farleygreene.com/products/sm-rota-series

See the Sievmaster® Rota Range in Action

The Rota series demonstrates efficient, hygienic screening in a compact design. Therefore, its small footprint is ideal for many facilities. Furthermore, this short video highlights how the Rota range handles high-volume sieving for both wet and dry applications. Ultimately, the video shows the specific features of the machine and the diligent design Farleygreene prides itself on.

Watch the Rota Range Overview Video: Discover how Farleygreene’s rotary sieves deliver consistent, controlled performance across food, chemical, and pharmaceutical applications.

…………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………..

FAQs: Sievmaster® Rota 90

1. How does the Sievmaster® Rota 90 compare to other sieving machines?

The Rota 90 is a compact centrifugal sifter using high-speed rotating paddles to push product through a mesh cylinder. Unlike vibratory sieves, it operates non-vibratory and dust-tight, providing consistent, hygienic screening in small production spaces.

2. What materials can the Rota 90 process?

It handles compacted fine powders and granules across food & drink and chemical industries. The machine works with wet or dry products, breaks down agglomerates, and delivers accurate particle separation.

3. How does the Rota 90 improve hygiene?

The fully enclosed stainless-steel design prevents dust from escaping and contamination. Tool-free mesh access and easy-clean components simplify cleaning between product runs.

4. Can the Rota 90 handle high-volume production?

Yes. Despite its compact size, it offers high-volume bulk sieving, making it suitable for continuous production. The non-vibratory design reduces stress on the product while maintaining throughput.

5. How easy is it to maintain the Rota 90?

Maintenance is simple. The mesh cylinder and paddles are fully removable without tools, making cleaning and inspection quick. Regular checks of paddles, seals, and mesh ensure long-term reliability.

6. Is the Rota 90 suitable for hazardous or ATEX-rated environments?

Yes, you can configure it with ATEX-rated options to operate safely in dust or combustible powder environments.

7. Can the Rota 90 be integrated into existing production lines?

Absolutely. It can be installed under bulk bags or container systems, and it works with most mechanical or pneumatic conveyors. Its compact footprint allows easy integration, even in tight spaces.

8. What kind of products benefit most from the Rota 90?

Products requiring accurate particle sizing, deagglomeration, or consistent quality control benefit most. This includes sugar, confectionery, chemical powders, biscuits, and other granular or powdered materials.

9. How often should the machine be inspected?

Routine inspections of paddles, mesh, and seals are recommended. Frequency depends on material type and usage intensity. Additionally, checking before each production cycle ensures optimal performance.

10. How can I see the Rota 90 in action?

Contact our team to arrange a demonstration: [email protected].