Requirement

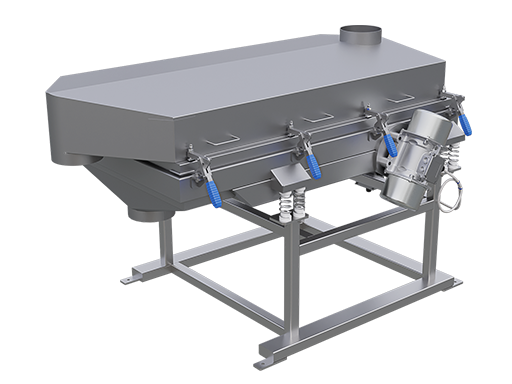

The UK’s leading manufacturer of vitamins, minerals and nutritional supplements, IVC Brunel Healthcare, recently added a second production line to their new top-of-the-range Soft Gel Facility in Swadlincote, Derbyshire. Due to high demand from their new facility an updated Soft Gel capsule sorter was required and Brunel called upon Farleygreene to help them out.

“After contacting Farleygreene, who had originally made the very first one, they were more than happy to come to site to see what new version they could offer”, explains Chris Tilson Manufacturing Manager. “After taking a number of dimensions, the engineering team at Farleygreene came back with a number of options for us to consider.”