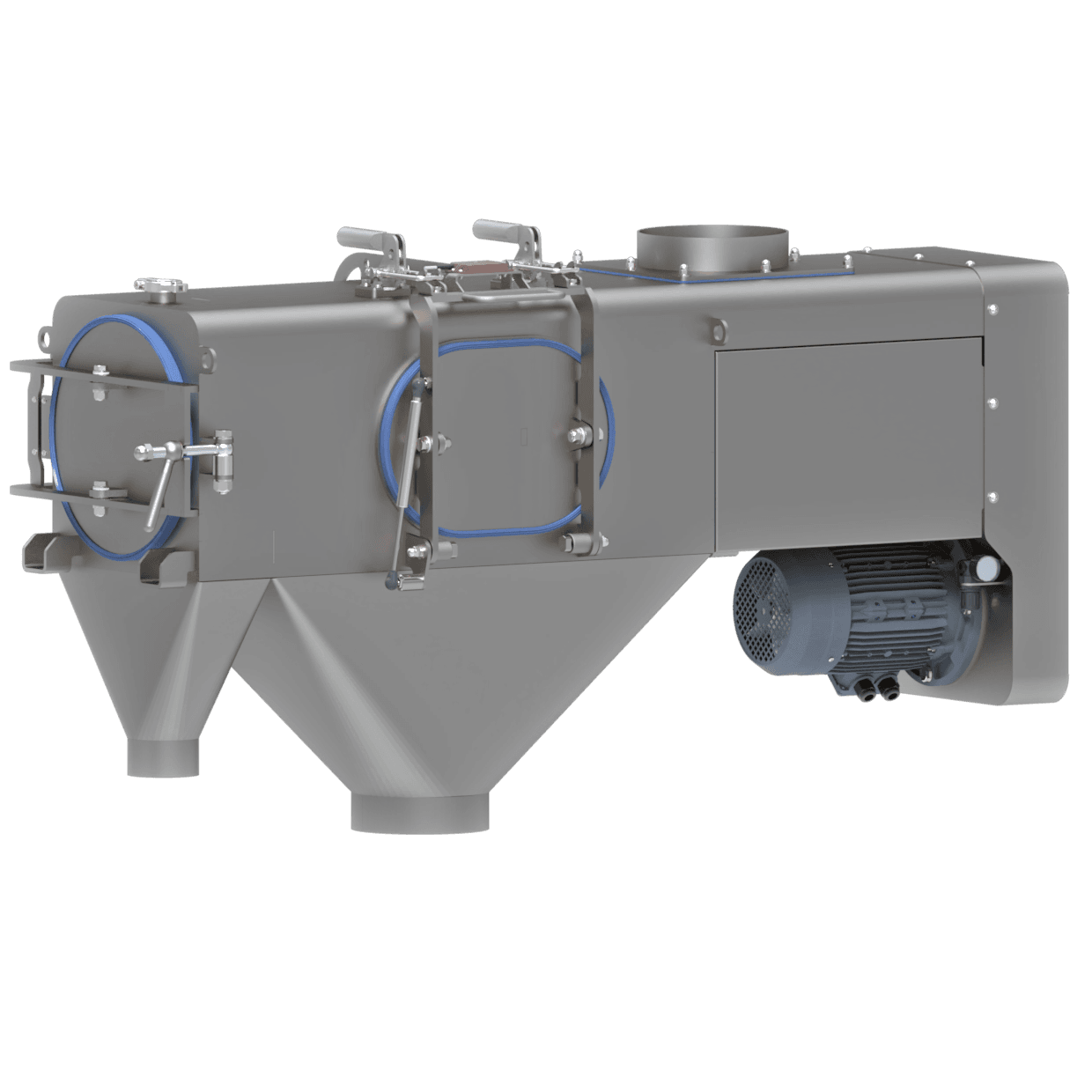

What is the Sievmaster Slimline Sieve?

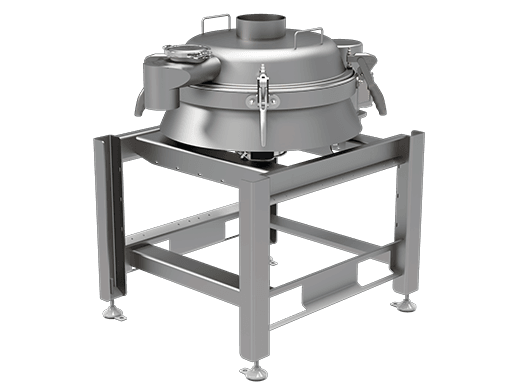

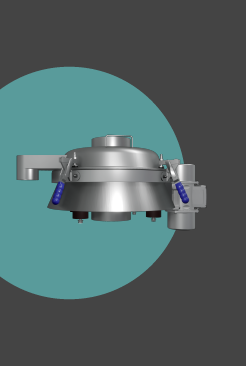

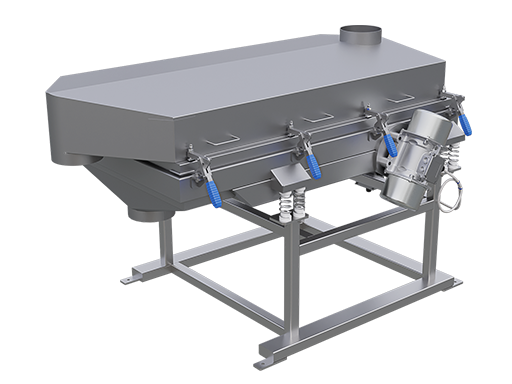

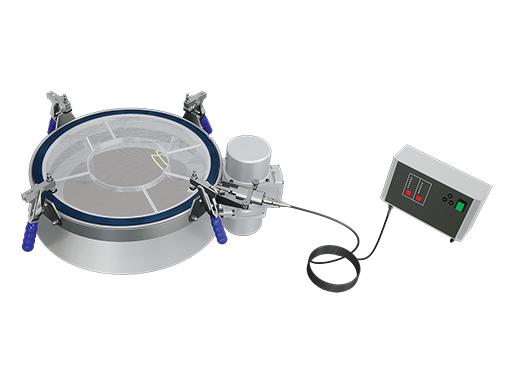

A highly effective check screener available in four different diameters.

Designed to be gravity fed as part of a continuous production line or stand alone on mobile or static frames, these sieves are capable of handling both wet and dry applications.

Pneumatic lifting and lowering systems are available on larger models to increase ease of personnel interaction, reducing health and safety risks, and provide ample access to the mesh screen for inspections and removal for cleaning and mesh replacements.

For factories with limited room, different styles of vision inspection ports are offered.