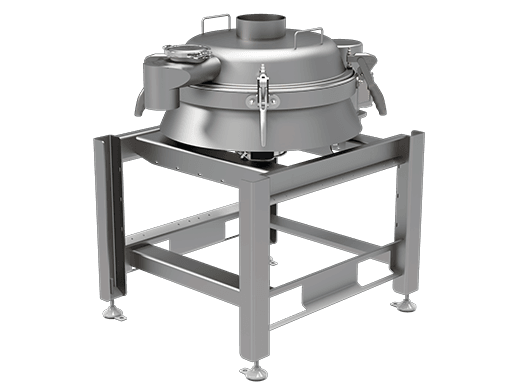

What is the Sievmaster 700-ST?

The 700-ST combines a hygienic design with fine control of the vibration, allowing for highly efficient sieving compared to other similarly sized industrial sieves, without compromising on the quality of the product.

Fully stainless steel contact parts and external components mean it can be used in the most demanding environments, whilst tool-free, quick change mesh screens minimise downtime between batches.

It is available with a mobile base assembly as standard or can be supplied with adjustable bolt-down feet, and can be upgraded to fully stainless steel construction throughout.