What is the Sievmaster Ultrasonic System?

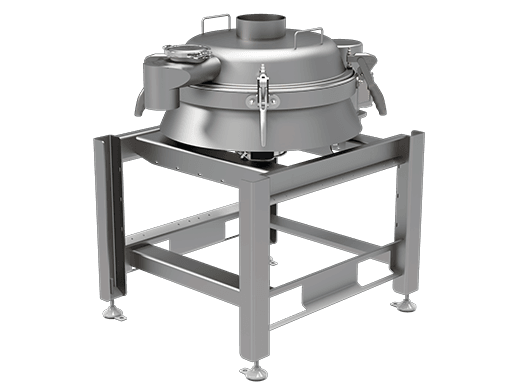

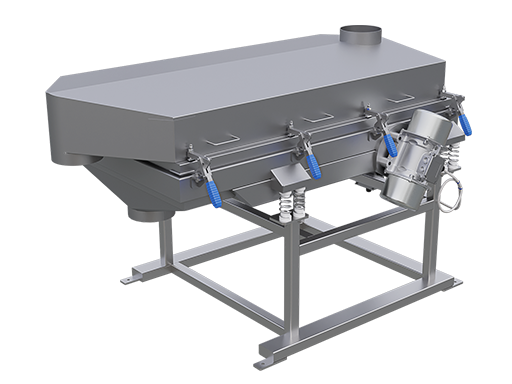

Known also as an “ultrasonic deblinding system”, this set of supplementary equipment is used to prevent mesh blockage and blinding to deliver efficient sifting of powders and accelerate throughput.

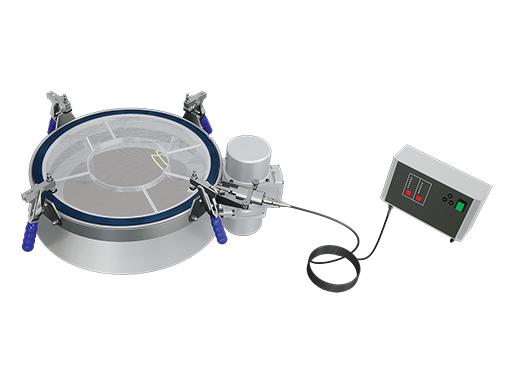

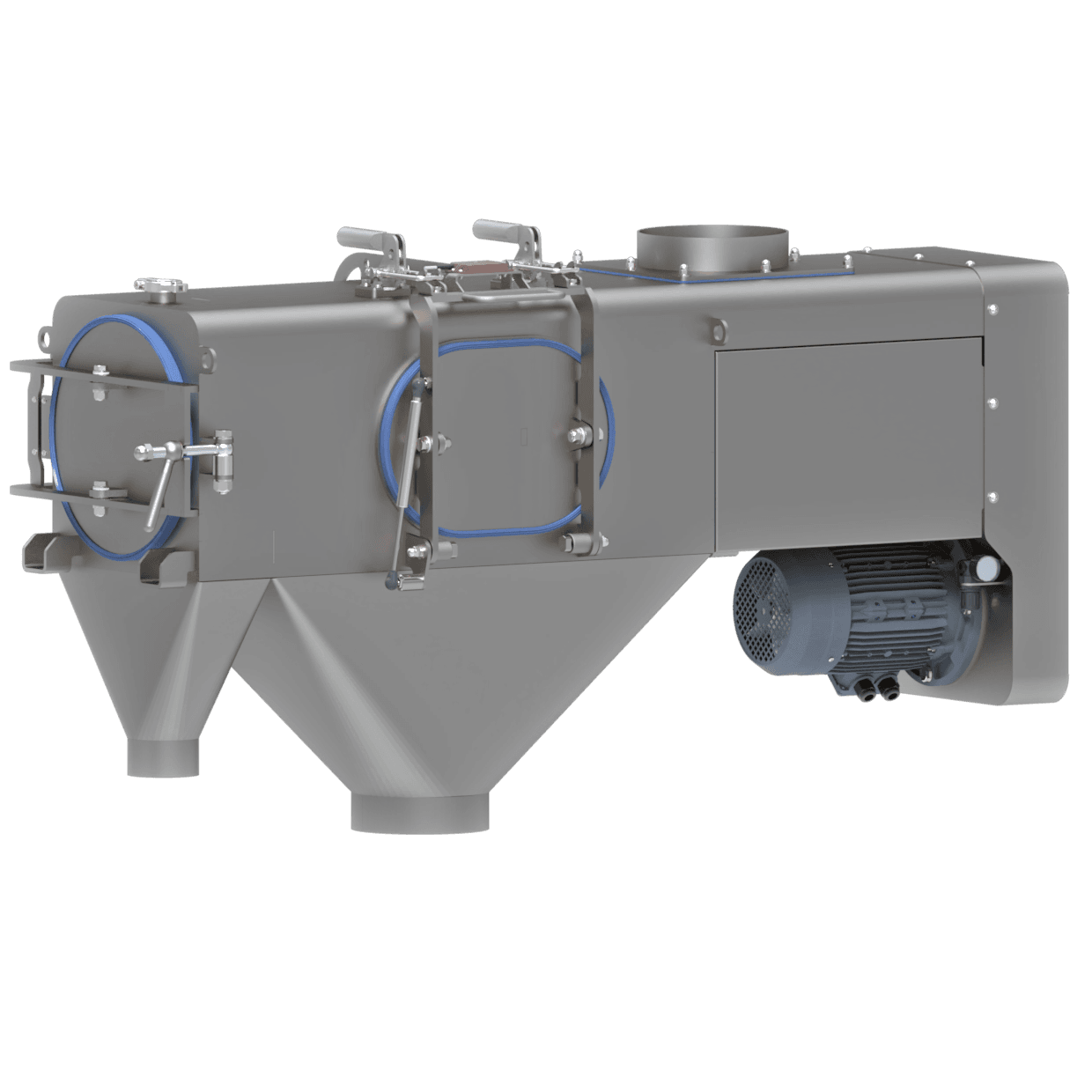

The ultrasonic system is designed to fit within most Sievmaster sieving machines. It uses a generator box connected to an externally mounted converter which applies ultrasonic vibrations to a waveguide and transmits them to a mesh screen.

It applies a continuously varying wave, known as ‘frequency variation’, rather than ‘single wave’ resonance frequency. This solves common problems such as heating and ‘hot spots’ that run the risk of causing premature mesh failure.

The Sievmaster Ultrasonic System is available with a variety of different options depending on each user’s requirements. Please get in contact with your local Farleygreene distributor or with us directly to find out more about specifications for the ultrasonic system.