Solution

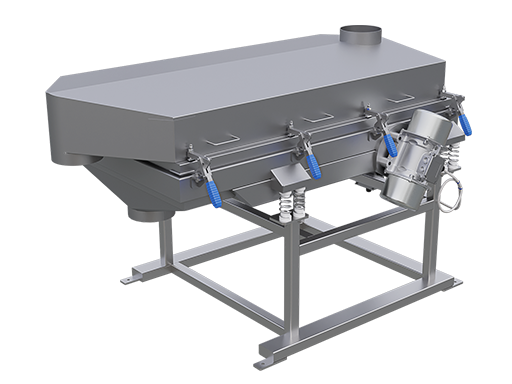

The company had a major problem with their tomato handling. Tomatoes were supplied in large cans and contained significant quantities of liquid which ideally needed to be drained off prior to spreading onto the pizza base. A too wet product resulted in too much liquid being frozen onto the base thus when cooked it resulted in the liquid saturating the base making it ‘soggy’. The Segregator 42 machine was supplied fitted with a 6 mm perforated screen inclined at 15 deg. The fines discharge was fitted with a catch tank with a RJT threaded hose take off.

The operator emptied the contents of the cans directly to the back end of the machine and the vibratory action and inclination of the screen gently allowed the tomatoes to pass to the end where they were caught in a catch tray. The liquid passing through the perforated plate to the tank and disposal.