Solution

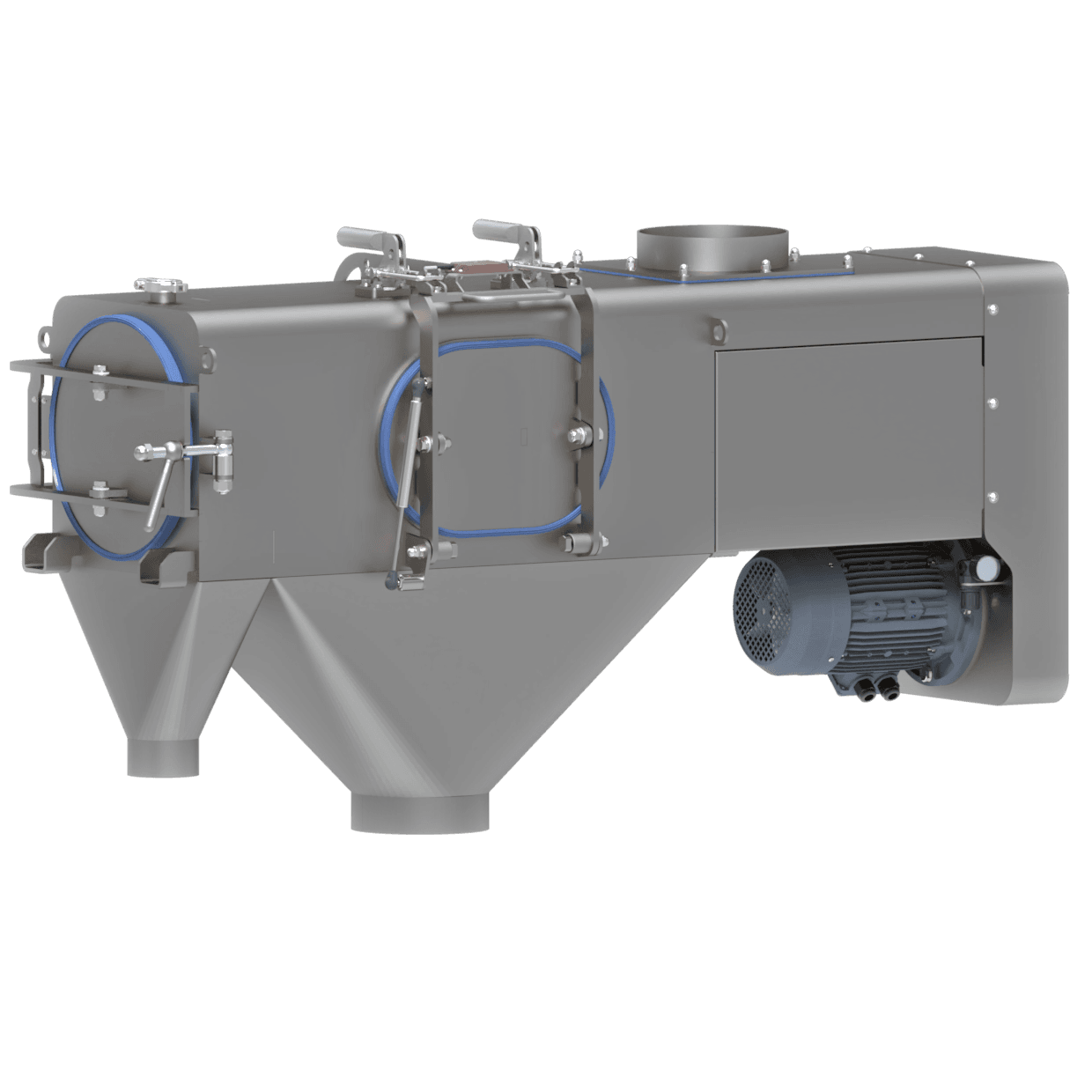

Farleygreene supplied a Rota 400-ST centrifugal sifter which provided twice the throughput of the original Rota 200 machine, because of its double auger and paddle blade configuration. The feed hopper was modified to provide a moderate sized bulk hopper and the unit was mounted upon a stainless steel stand. Farleygreene also supplied the lifting and tipping unit to feed the sifter, along with the belted conveyor to take the product away for packing.

The Sievmaster Rota was fitted with a perforated mesh basket which creates a grating effect to the biscuit, grinding it down to the size required. Biscuits, being of a high fat content, can clog a normal grinding system but the action of the blades prevent this and allow for very fast production.