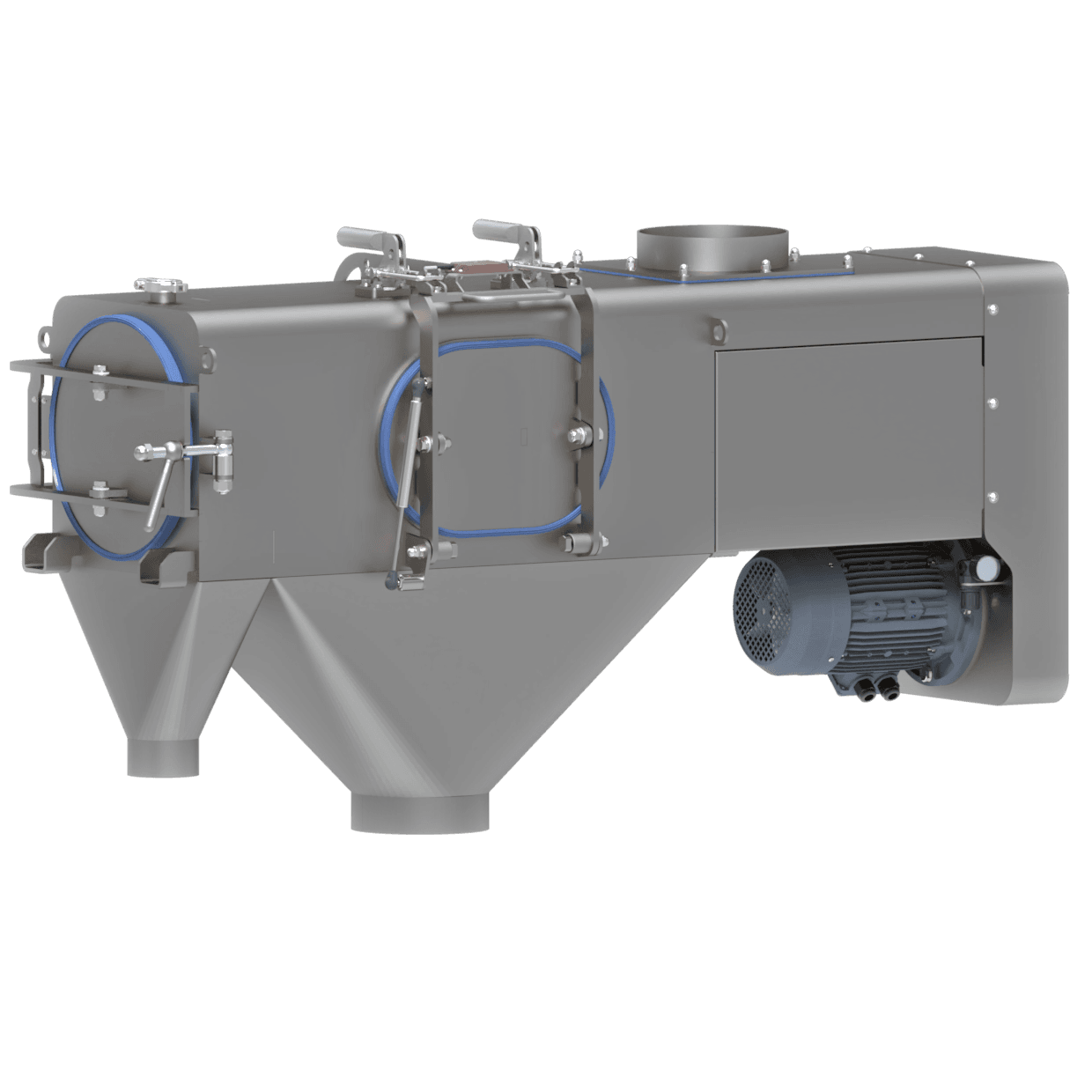

A specially designed Sievmaster Rota 200-ST centrifugal sifter unit on a bespoke support frame was supplied.

The unit was fitted with bolted panels which only allowed access by maintenance engineers. The unit was nitrogen purged to overcome any explosive risks and was fitted ‘in-line’ to the system by being fed by a fixed piping arrangement and discharging directly to the sealed mixer.

The oversize was minimal but retrieved via a special catchment container fitted with double valve system. The ‘aggressive’ auger and paddle blade assembly continuously broke down any lumps within the enclosed body of the machine. The machine was interlocked to all removable panels to the nitrogen purge control system.