A sieving machine was required to break down blocks of honeycomb and separate it into five grades.

The client needed to supply various sized pieces of honeycomb product for confectionery and ice cream manufacture.

They required a machine to break down blocks of ‘honeycomb’ and separate it into five grades.

A Rota was used to break down the honeycomb confectionery into various sizes and the fines (product discharge) were then transferred to the Sievmaster Multiscreen 1200 grading sieve for further processing.

The Multiscreen divided the product into large to fine groups each being collected within plastic containers. The whole arrangement was supplied with full control and safety system.

The client needed to supply various sized pieces of honeycomb product for confectionery and ice cream manufacture. They required a machine to break down blocks of ‘honeycomb’ and separate it into five grades.

The product was lifted and tipped directly from EuroBin type containers, fed directly into a grading separator below and then into small containers.

A Sievmaster Rota 200 centrifugal sifting machine (mounted upon a stainless steel frame) was supplied, along with a lift and tip unit designed to elevate a 200 litre EuroBin of product. A specially made bulk hopper/vibratory feed arrangement was assembled at the inlet to the centrifugal sifter, ensuring a direct flow of product.

The Rota was used to break down the honeycomb confectionery into various sizes and the fines (product discharge) were then transferred to the Sievmaster Multiscreen 1200 grading sieve for further processing. The Multiscreen divided the product into large to fine groups each being collected within plastic containers. The whole arrangement was supplied with full control and safety system.

The client was able to satisfy the requirement with a standalone system and without the need to obtain equipment from various suppliers. The customer was also able to make use of each size of final product for different clients, even making use of product that was previously thrown away.

The client needed to supply various sized pieces of honeycomb product for confectionery and ice cream manufacture. They required a machine to break down blocks of ‘honeycomb’ and separate it into five grades.

The product was lifted and tipped directly from EuroBin type containers, fed directly into a grading separator below and then into small containers.

A Sievmaster Rota 200 centrifugal sifting machine (mounted upon a stainless steel frame) was supplied, along with a lift and tip unit designed to elevate a 200 litre EuroBin of product. A specially made bulk hopper/vibratory feed arrangement was assembled at the inlet to the centrifugal sifter, ensuring a direct flow of product.

The Rota was used to break down the honeycomb confectionery into various sizes and the fines (product discharge) were then transferred to the Sievmaster Multiscreen 1200 grading sieve for further processing. The Multiscreen divided the product into large to fine groups each being collected within plastic containers. The whole arrangement was supplied with full control and safety system.

The client was able to satisfy the requirement with a standalone system and without the need to obtain equipment from various suppliers. The customer was also able to make use of each size of final product for different clients, even making use of product that was previously thrown away.

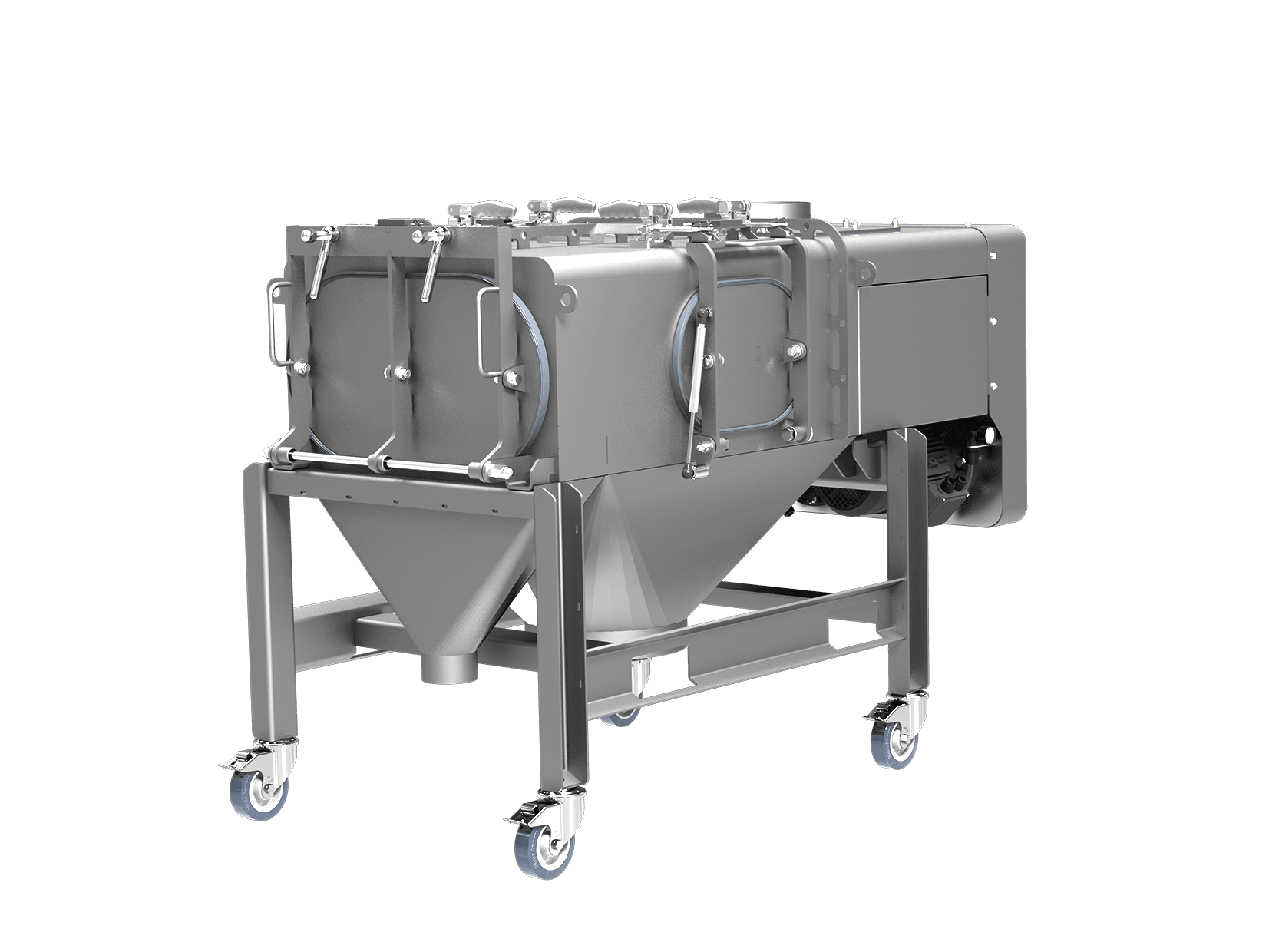

The Sievmaster Multiscreen Range uses a motor underneath a series of mesh screens with decreasing aperture sizes to achieve different cuts of product.

The Sievmaster Rota Range uses a set of high-speed rotating paddles to direct fine product through a mesh cylinder. The FG Rota series is offered in 3 sizes (from smallest to largest): 90-C single basket, 180-C single basket and 360-C twin basket variants.

Make use of our demo fleet with two-weeks for free, or our in-house testing facility.